WENZHOU YOYOND LIQUID EQUIPMENT CO.,LTD

- MSN:yoyond@hotmail.com EMAIL: yoyondsales@gmail.com

Product Name: Sine Pump

Sine Pump is the only truly universal pump. With its host of design advantages, Sine Pump is ideal for your process. Sine Pump meets or exceeds sanitary requirements.

Whether you nee to transfer delicate cheese curd, or pump shear sensitive adhesives, you can count on Sine Pump.

Typical Applications

- Prepared Foods-soups, stews, chili, deli salads, condiments;

- Dairy-cottage cheese, yogurt, processed cheese, ice cream;

- Meats-emulsions, comminuted meats, chicken parts;

- Bakery-fruit fillings, batters, and frosting;

- Confection-caramel, corn syrup, chocolate, fondants;

- Beverage-juices, concentrates, syrups, yeast slurries;

- Cosmetics-lotions, creams, conditioners, shampoo, tooth paste;

- Pharmaceuticals-gels, cough syrups, ointments;

- Industrial-silicone, nylons, coatings, latex, starches, dyes;

Features:

- Low Shear-Gentle wave rotor handles fragile solids and maintains product integrity.

- Powerful Suction-Patented design assures powerful suction for high viscosity applications.

- Low Pulsation-Constant volumetric displacement creates a smooth and consistent flow.

- Easy Maintenance-One rotor, one shaft, and one seal assembly equate to simple, economical maintenance;

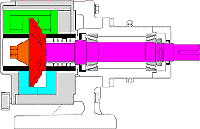

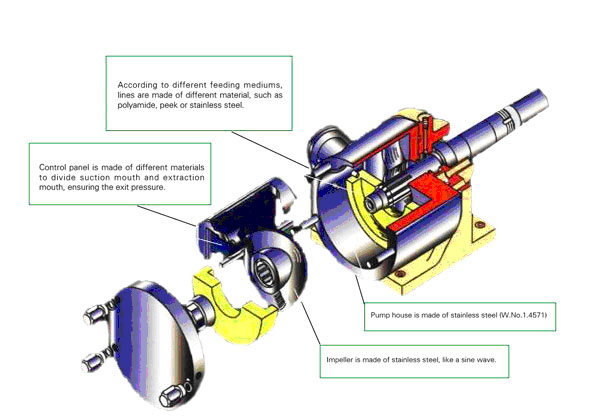

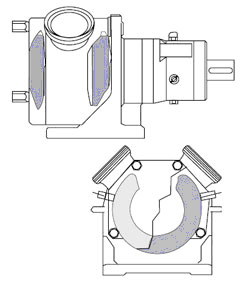

Sine pump: Special two sine-curve-like vane is taken, instead of rotor, epicyclic gear or piston, and it runs with a movable panel and a fixed line, forming a special volume pump and realizing liquid super low shear, without pulse feeding, although in condition of 10bar back pressure (water feeding), there won’t be any movement on pressure gauge.

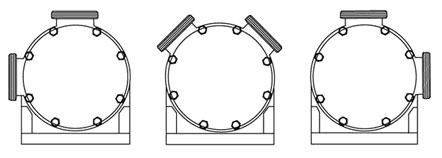

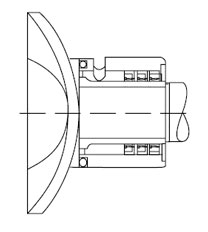

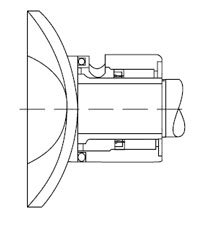

Many connection forms: clamped, threaded and flanged. Diagram below shows the connection directions of inlet and outlet which can be selected.

Triple lip shaft seal:

Low pressure application. Lip shaft seal is normally installed in a single shaft sleeve, without any damage on driving shaft.

Other cleaning function can be added on shaft seal:

For 3A standard pump, single stage built in mechanical seal is taken to ensure cleaning, cooling and CIP cleaning and sterilization.

Single or double mechanical seals:

The mechanical seal of sine pump conforms to food sanitary standard, ensures the cooling and sterilization are meeting the requirements of CIP (cleaning in place) and SIP (sterilization in place). Meanwhile, all seal systems can be replaced conveniently

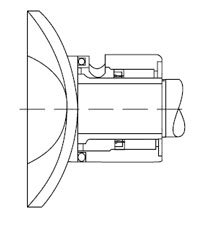

Heating or cooling:

Many products (for example: sugar manufacturing industry) need to be heated or cooled. Jacketed pump body is optional and can be connect to any hot water supply system safely and conveniently.

Driving method in special application:

As per different application, fixed or flexible rotation speed adjustment method can be selected.

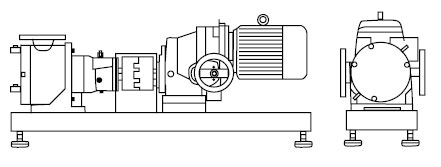

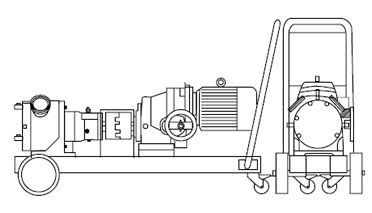

Motherboard: with coupling protective device, made of stainless steel.

Both methods are equipped with round feet, the height of it can be adjusted or can be brought outdoor. We also can provide a special solution.

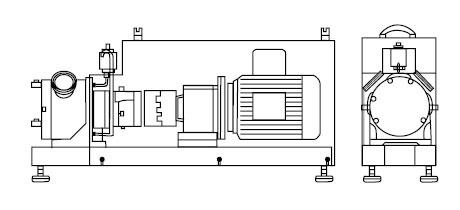

Outer casing housing: applicable for extreme humid conditions

Driving motor can be protected specially by a stable housing. An open ventilation hole can ensure the safety of cooling driving system.

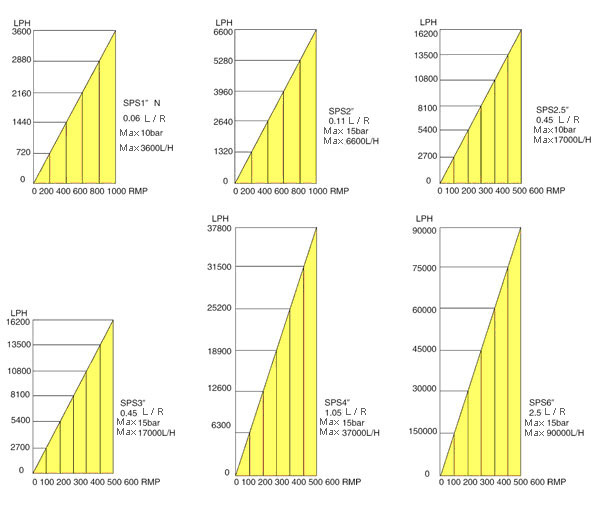

Discharge Characteristic Curve: